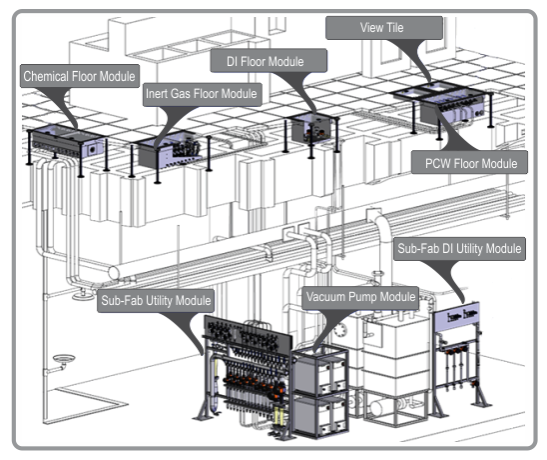

Diversified Fluid Solutions Tool Install Hook-Up Modules combine the established, innovative modular engineering experience of NEHP and the strength of DFS manufacturing capabilities. These modules are designed to be the utility delivery building blocks when a new piece of equipment is being installed.

This modular approach reduces installed cost by up to 20%, shrinks installation schedule by a third, reduces overall utility systems' footprint, simplifies coordination, reduces waste by enabling the reuse of utility delivery sub-systems, enables easy tool relocation, and efficiently extends the lifetime of the tool.

We have a substantial library of semiconductor processing tool platforms, where existing engineering designs will be tailored to the exact customer needs and space circumstances. Please see the Tool Installation Module Selection Table for a partial list of some of these platforms and the various standardized modules associated with them. This will reduce engineering, design and fabrication costs and speed the time to tool qualification.

We work closely with our customer's existing engineering firms, trades, and construction contractors to optimize tool installation project results, deliver the highest value to the tool owner, reduce waste, and maximize efficiency of the entire process. This team approach has roots in the proven Integrated Project Delivery (IPD) approach.

We strive to maintain an innovation rhythm to create new efficient and effective solutions in a methodical and controlled fashion. Our approach utilizes the benefits of experience while enabling the integration of state-of-the-art technology. Ultimately we succeed when we are able to sharpen our customers' competiveness and continuously increase their productivity.

Our manufacturing technology facilitates utility delivery systems compactness, standardization and quality control and enables the integration of smart components that provide process data and control capabilities if desired. Such smart component integration and associated control software are inevitably the future of manufacturing technology, and nearly impossible to fabricate, program and integrate using traditional stick-build methods.

Considering the industry's varying technology lifecycles, the end of the tool's useful life in one factory typically means the beginning of a new life at a different factory. Having the modular utilities delivery building blocks as part of the tool's entire operating system will enable the maximization of the tool value at the transition from one factory to the next. If a customer decides to keep the tool, but move it to another location, the hook-up modules provide maximum portability of the tool and its associated utility sub-systems, preventing waste of pipe and components.

Contact us for all your tool installation needs. We can start building from PIDs, existing tool installations or Tool Connect requirements. Our team has extensive expertise in a wide range of process tools and equipment installations. We can ship modules to your site or perform the entire on-site installation using our field service team for a complete turnkey package. We have successfully completed installations at facilities worldwide.

- Tool arrival-to-operational = 90% faster

- Reduce total installed cost up to 30%

- Optimize corrdination between design & construction

- Improved space utilization and layout flexibility

- Increase tool value to future buyers

- Unmatched modularization experience

- Enable smart control technology

For more information: 208.489.0053 or email info@dfsolution.com